Description

- The cylinder of fast forging hydraulic press is mainly processed by rolling to a certain extent, and the surface residual pressure is left on the surface to a certain extent, which is helpful to close the small cracks on the surface. In this way, the corrosion expansion is hindered to a certain extent, so as to improve the corrosion resistance of the surface, delay the generation or expansion of fatigue cracks, and thus improve the fatigue strength of the cylinder.

- Riveting welding is especially suitable for joining parts made of different materials, such as plastic and metal. One part has a riveting post that goes into the hole of the other part. Then through the cold flow of plastic or melting, the riveting column deformation, forming a rivet head, the two parts mechanically locked together. The process is fast and economical, and has the advantage of not consumingrivets and screws.

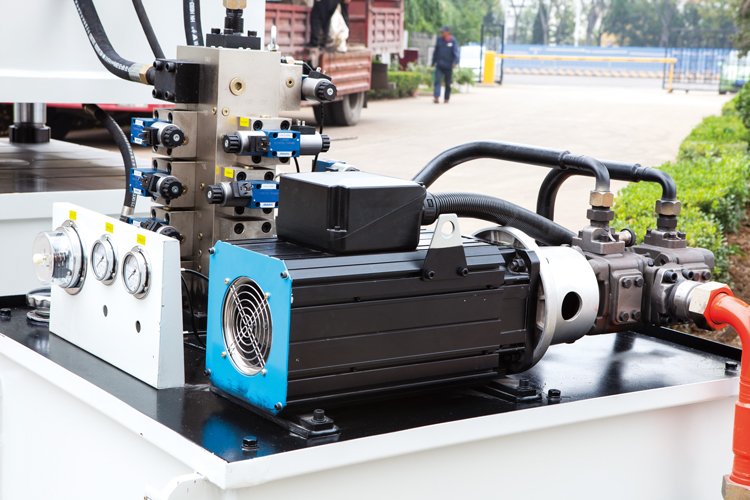

- Advantages of servo motor: Precision: closed-loop control of position, speed and torque is realized; The problem of stepping motor is overcome. speed: high speed performance, generally rated speed can reach 2000 ~ 3000 RPM; adaptability: strong overload resistance, can withstand three times the rated torque load, especially suitable for the occasion of instantaneous load fluctuation and fast starting;

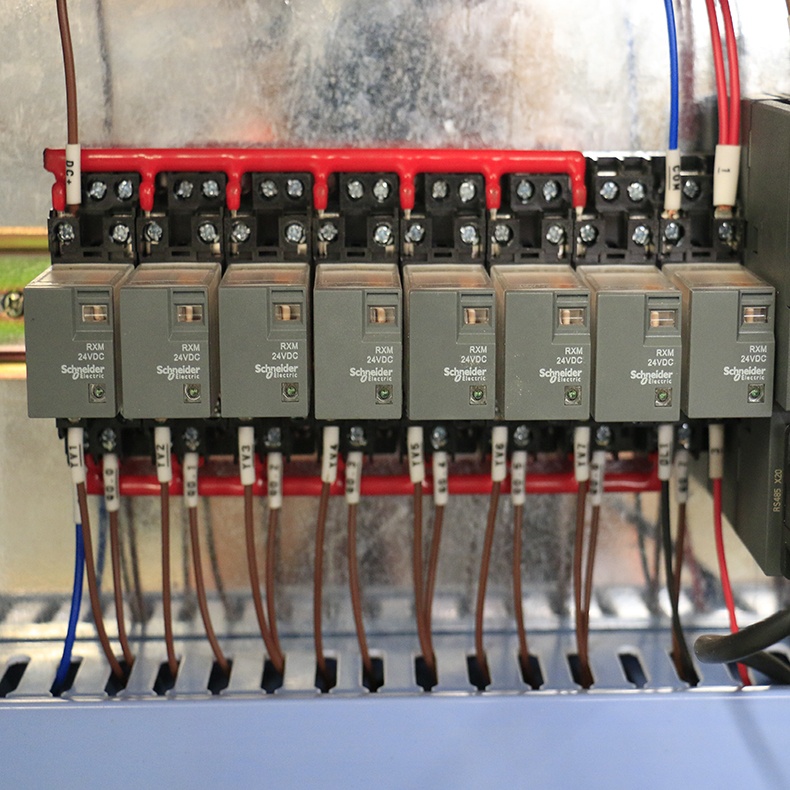

- Schneider ELECTRICAL COMPONENTS, in line with international standards, beautiful appearance, special high-quality copper inDENter, electric screwdriver fixed torque torsion, to ensure that the wire in the transport and use of stable and reliable.

This series of hydraulic press is suitable for stretching, bending, flanging, cooling, blanking and other processes of metal materials.