Description

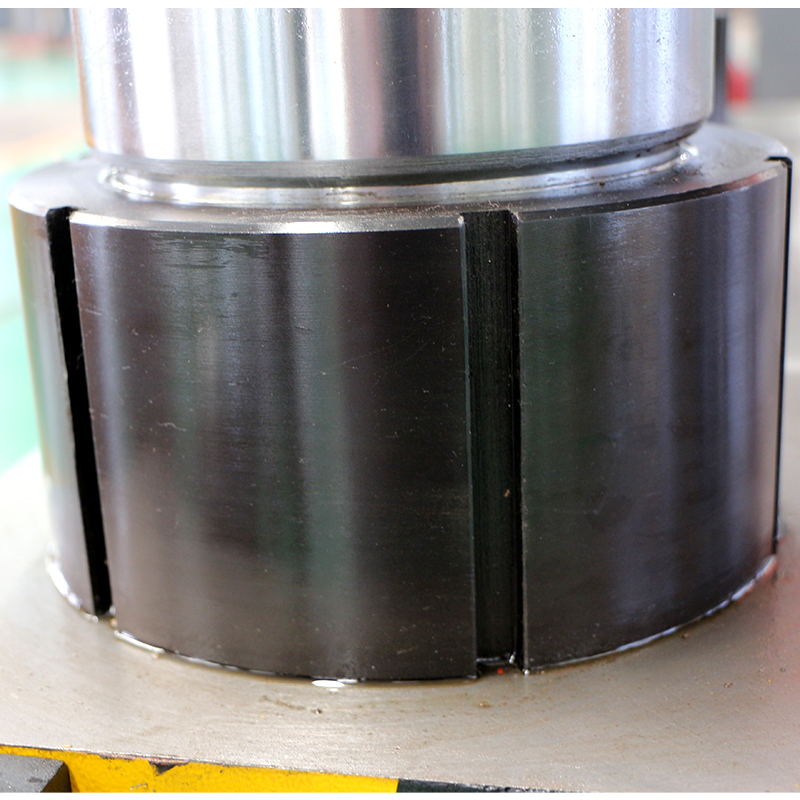

- The cylinder of fast forging hydraulic press is mainly processed by rolling to a certain extent, and the surface residual pressure is left on the surface to a certain extent, which is helpful to close the small cracks on the surface. In this way, the corrosion expansion is hindered to a certain extent, so as to improve the corrosion resistance of the surface, delay the generation or expansion of fatigue cracks, and thus improve the fatigue strength of the cylinder.

- Safe and reliable, using advanced optical software and optimized structural seal design, with strong environmental adaptability, quiet and smooth rotation, withstand strong collision and impact, to ensure that the lamp can be in the harsh environment for a long time stable and reliable work.

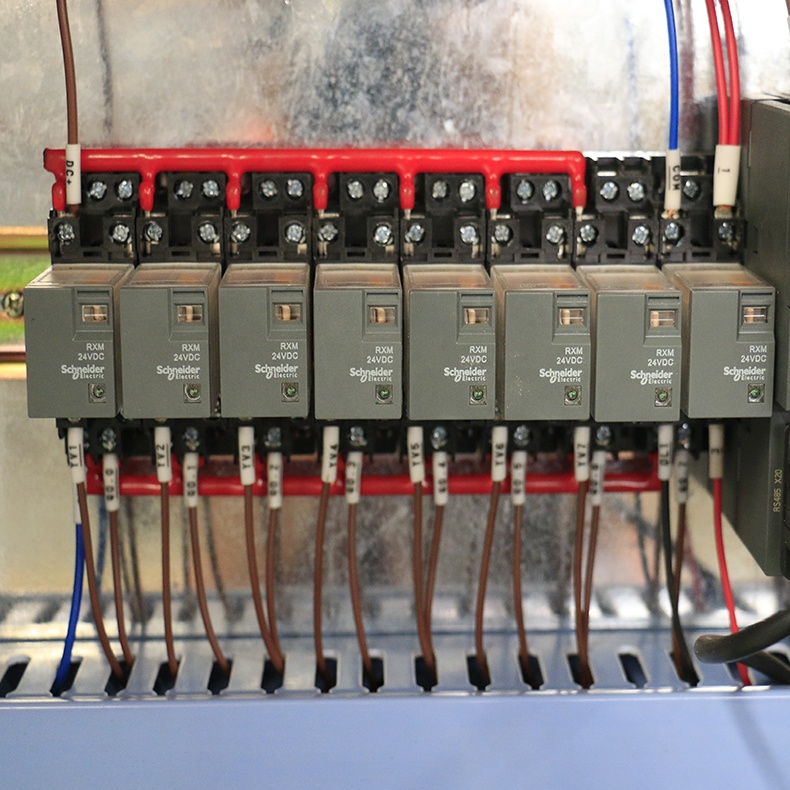

- Schneider ELECTRICAL COMPONENTS, in line with international standards, beautiful appearance, special high-quality copper inDENter, electric screwdriver fixed torque torsion, to ensure that the wire in the transport and use of stable and reliable.

- The post adjusting nut blackening process strengthens the corrosion resistance of screws and other fasteners after blackening, enhances the surface brightness, and plays an anti-rust role on the fastener surface; Heating blackening also helps to reduce the internal stress of fasteners.

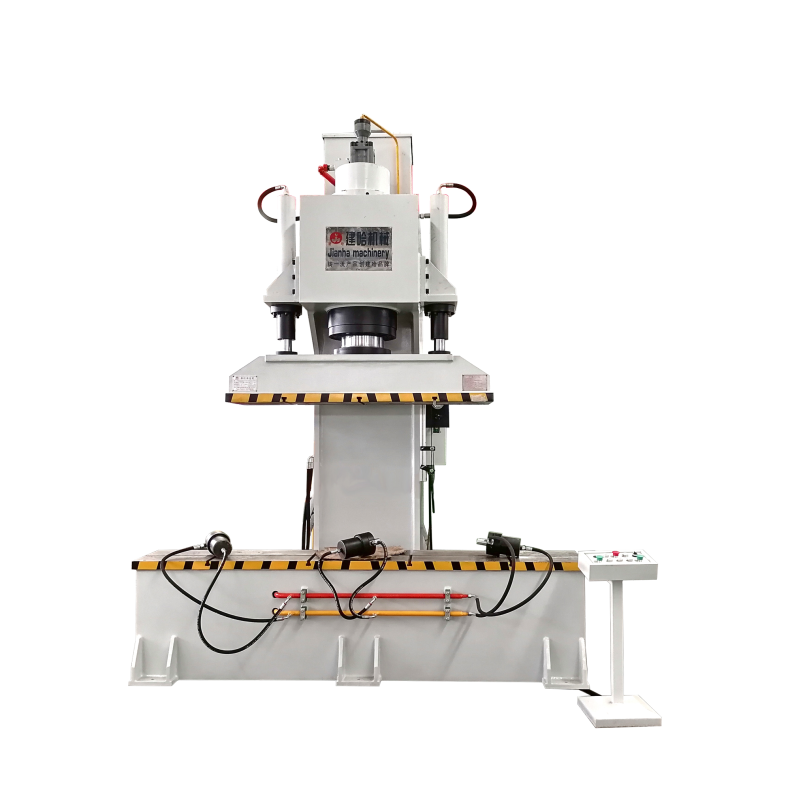

This series of hydraulic press is suitable for stretching, bending, flanging, cooling, blanking and other processes of metal materials.