| Model | VTC80 |

| CNC System | Siemens/Mitsubishi/Fanuck etc. |

| TRAVEL |

| X-axis | 670 |

| Z-axis | 900 |

| CAPACITY |

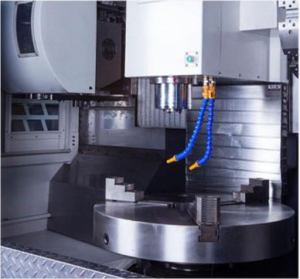

| Max.swing dia. | Φ1000 mm |

| Max.turning dia. | Φ800 mm |

| Max.turing High | 700 mm |

| SPINDLE |

| Max-Spindle speed | 800 rpm |

| Spindle motor power(servo motor) | 22Kw |

| Spindle type | FAG |

| Spindle shaft hardness | NN3036K |

| Dimension-LD/OD/WIDTH | φ180×φ280×74 |

| Rear bearings | NN3028K |

| Dimension-LD/OD/WIDTH | φ140×φ210×53 |

| Speed-down | 01:02 |

| Chuck &Automatic lathe turret |

| Chuck type | Hydraulic chuck |

| Dia.Chuck | Φ 630mm |

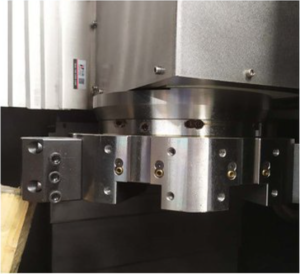

| Lathe turret work station | Horizontal 8-station |

| SLIDE WAY |

| X-axis slide way | 2, width 45mm |

| Z-axis slide way | 2, width 55mm |

| Ball screw |

| Ball screw accuracy | Level C3 |

| Ball screw diameter X/Z | X:Φ40 Z:Φ50 |

| ACCURACY |

| Repeat positioning | ±0.008mm |

| Positioning | ±0.012mm |

| Least input increment | 0.001mm |

| POWER REQUIRE |

| Power source | 3¢-AC 380V 50Hz±5% |

| Working environment temperature and humidity | Temperature 5~38°C/humidity <85% |

| OTHERS |

| The hydraulic pressure stands | 1.5KW/50Hz-40L |

| Cross weight | 10T |

| Packing dimensions | 2480*2200*3350mm |

| |

| |