Description

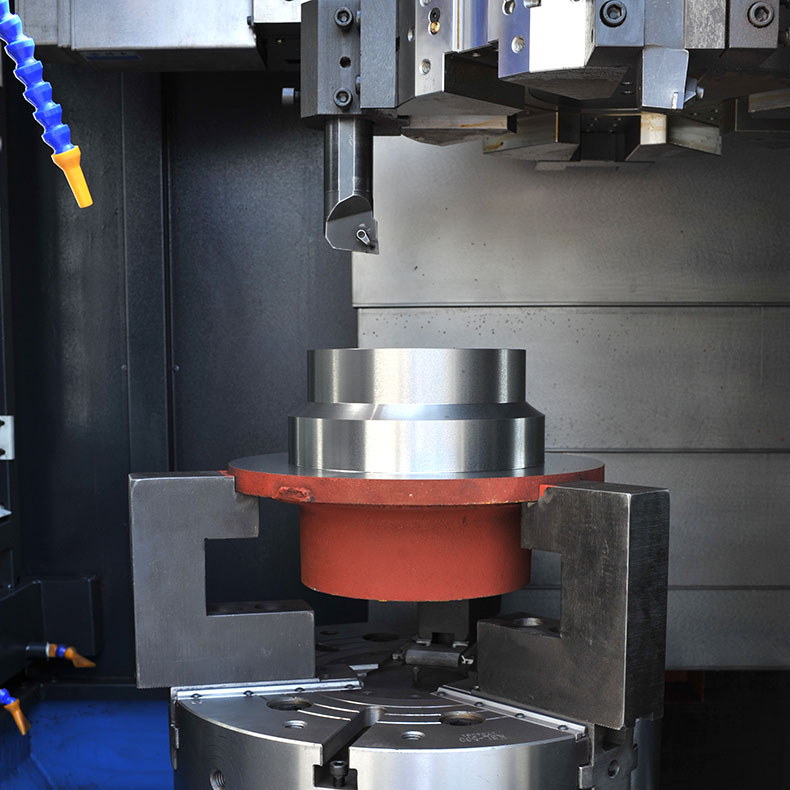

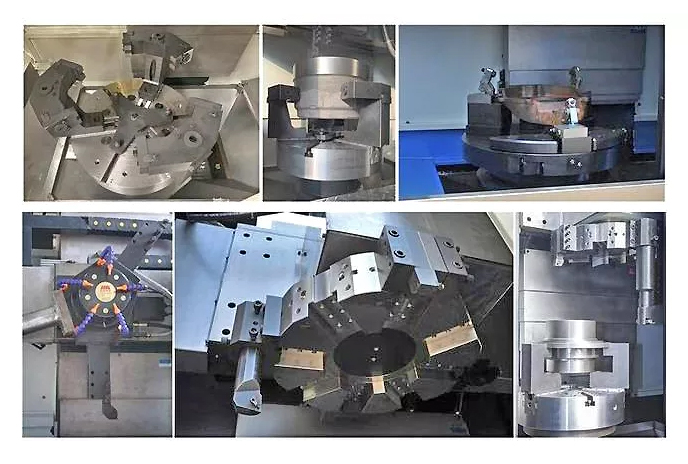

This is a multi-purpose CNC automatic machining vertical lathe, which is used to process the inner and outer cylindrical surfaces, conical surfaces, end surfaces, grooving and chamfering of components. The CNC vertical lathe is especially suitable for the processing of disc components such as automobile wheel hubs, brake valleys, flywheel housings, clutch housings, pressure plates, and differential housings..

This is a multi-purpose CNC automatic machining vertical lathe, which is used to process the inner and outer cylindrical surfaces, conical surfaces, end surfaces, grooving and chamfering of components. The CNC vertical lathe is especially suitable for the processing of disc components such as automobile wheel hubs, brake valleys, flywheel housings, clutch housings, pressure plates, and differential housings..This is a multi-purpose CNC automatic machining vertical lathe, which is used to process the inner and outer cylindrical surfaces, conical surfaces, end surfaces, grooving and chamfering of components. The CNC vertical lathe is especially suitable for the processing of disc components such as automobile wheel hubs, brake valleys, flywheel housings, clutch housings, pressure plates, and differential housings..

This is a multi-purpose CNC automatic machining vertical lathe, which is used to process the inner and outer cylindrical surfaces, conical surfaces, end surfaces, grooving and chamfering of components. The CNC vertical lathe is especially suitable for the processing of disc components such as automobile wheel hubs, brake valleys, flywheel housings, clutch housings, pressure plates, and differential housings..This is a multi-purpose CNC automatic machining vertical lathe, which is used to process the inner and outer cylindrical surfaces, conical surfaces, end surfaces, grooving and chamfering of components. The CNC vertical lathe is especially suitable for the processing of disc components such as automobile wheel hubs, brake valleys, flywheel housings, clutch housings, pressure plates, and differential housings..

1.The structure of CNC vertical turning tool rest is vertical or horizontal multi-station CNC tool rest, which can shorten the tool change time and improve work efficiency.

1.The structure of CNC vertical turning tool rest is vertical or horizontal multi-station CNC tool rest, which can shorten the tool change time and improve work efficiency.

2.The upper end of the spindle can be equipped with a disc table or a hydraulic chuck according to customer requirements, and a single-piston cylinder or a double-piston cylinder can be installed at the lower end of the spindle to control the workpiece and hydraulic chuck.

3.The CNC system can be equipped with Fanuck, Siemens, Mitsubishi, Guangzhou CNC, etc. according to customer requirements

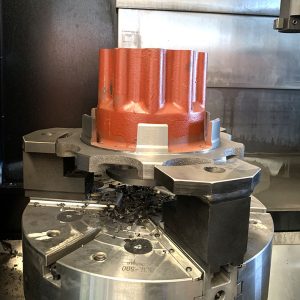

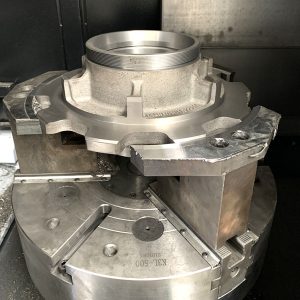

machining workpiece

machining workpiece